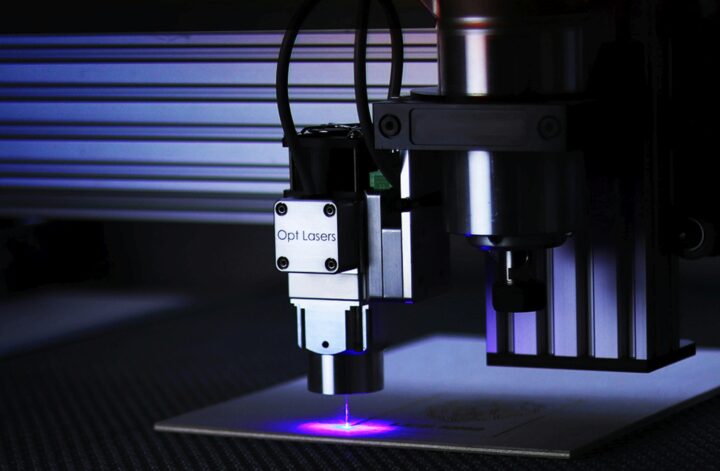

Laser cutting technology has revolutionized various industries by offering precision, speed, and versatility in material processing. This advanced method uses a high-powered laser beam to cut or engrave materials with remarkable accuracy. It is ideally suited for applications in sectors such as automotive, aerospace, electronics, and more. This guide delves into the myriad benefits of laser cutting, including reduced waste, enhanced efficiency, and the ability to produce intricate designs. Additionally, we will explore why businesses are increasingly adopting this state-of-the-art manufacturing technique to meet their production requirements and stay competitive in today’s fast-paced market.

Precision Cutting

One of the primary advantages of laser cutting is its exceptional precision. Highly focused laser beams enable intricate and detailed cuts with minimal errors. Whether working with metals, plastics, wood, or other materials, laser cutting consistently delivers precise and accurate results. This process uses a concentrated beam of light, directed by a computer, to cut or engrave materials with high accuracy. The technology facilitates complex shapes and designs that would be challenging or impossible with traditional cutting methods, making it ideal for industries that demand perfection, such as aerospace, automotive, and electronics, where even the slightest deviation can lead to significant issues. Moreover, laser cutting reduces waste and increases efficiency, rendering it a cost-effective solution for various manufacturing needs.

Increased Efficiency

Laser cutting surpasses traditional methods in efficiency and productivity. The rapid speed and automation of laser cutting machines enable swift material processing, thereby reducing production times and boosting output. This heightened efficiency not only conserves time but also lowers labor costs, making laser cutting a cost-effective solution for businesses.

Versatility

One of the primary advantages of laser cutting is its remarkable versatility. These machines can process a diverse array of materials, including metals, plastics, ceramics, and composites, accommodating different thicknesses and complexities. Whether it’s for intricate designs, prototypes, or large-scale production runs, laser cutting provides unparalleled versatility and flexibility, meeting the varied demands of multiple industries.

Minimal Material Waste

Laser cutting is an exceptionally efficient technique that significantly reduces material waste. Unlike conventional methods such as sawing or drilling, which generate excess material, laser cutting delivers clean, precise cuts with minimal kerf width. This precision minimizes material loss during manufacturing, resulting in cost savings and environmental benefits for businesses.

Intricate Designs and Customization

Laser cutting enables Salt Lake City businesses to bring intricate designs to life with remarkable precision. This advanced technology uses highly focused laser beams to cut through various materials, including metals, plastics, and wood. It allows for the creation of intricate patterns, shapes, and details that traditional cutting methods—such as saws or knives—cannot achieve. This customization empowers businesses to produce unique, innovative products that stand out in the marketplace, offering boundless creative possibilities.

Whether for industrial parts, artistic projects, or custom promotional items, laser cutting significantly enhances the quality and appeal of the final product. By incorporating laser cutting into their production processes, businesses can boost efficiency and accuracy, unlocking new levels of innovation and design versatility.

Conclusion

Laser cutting technology presents numerous advantages for businesses. It offers precision cutting that ensures exact dimensions and clean edges, boosts efficiency to accelerate production processes, and provides versatility to cut a variety of materials, from metals to plastics. Additionally, it reduces material waste, making operations more cost-effective and environmentally friendly. By adopting laser cutting technology, businesses can enhance their competitiveness, lower overhead costs, and unlock new opportunities for innovation and customization. This technology enables the creation of intricate designs that were previously unattainable with traditional methods. Say farewell to outdated cutting techniques and welcome sharper, faster, and superior results with laser cutting. This advanced technology not only elevates product quality but also streamlines workflow, making it an invaluable asset for any forward-thinking company.