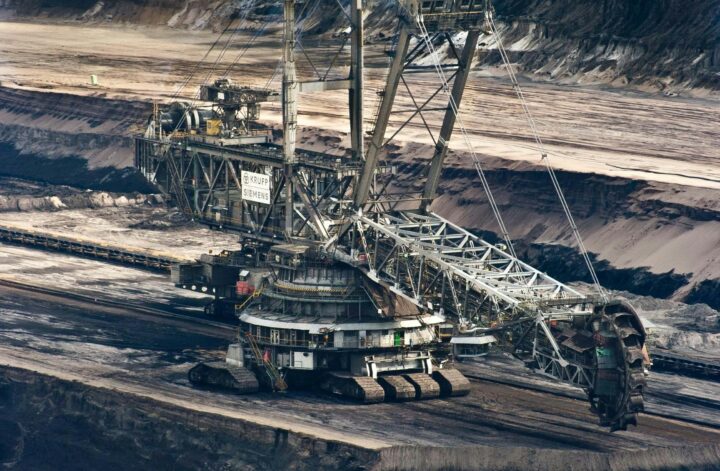

The mining industry is a cornerstone of global commerce, providing essential raw materials that fuel countless industries. However, it’s also one of the most hazardous sectors, with workers frequently exposed to dangerous conditions. From underground mining operations to open-pit excavations, the unique challenges of mining demand a steadfast commitment to safety. This commitment not only protects workers but also enhances operational efficiency and profitability.

Overview of the Latest Safety Technologies and Innovations in the Sector

Safety technologies in the mining industry have evolved significantly over recent years. Innovations aimed at reducing risks and protecting workers include:

•Wearable Technology: Devices such as smart helmets and vests equipped with sensors can monitor vital signs, detect hazardous gases, and provide real-time location tracking. These features are invaluable in emergencies.

•Drones: Unmanned aerial vehicles (UAVs) are increasingly used for surveying hazardous areas, inspecting equipment, and monitoring environmental conditions, all without putting human workers at risk.

•Automated Equipment: Automation in mining equipment reduces human exposure to dangerous tasks. Autonomous trucks, drills, and loaders are becoming commonplace, minimizing the risk of accidents caused by human error.

•Real-Time Monitoring Systems: Advanced monitoring systems provide live data on various safety parameters, such as air quality, structural integrity, and equipment status. These systems enable swift responses to potential hazards.

Best Practices for Creating a Safety Culture Within Mining Operations

Building a robust safety culture is essential for minimizing risks in mining operations. Here are some best practices to foster a safety-first mindset:

1. Leadership Commitment: Safety must start from the top. Leaders should visibly prioritize safety, allocate resources to safety initiatives, and be actively involved in safety planning and reviews.

2. Comprehensive Training: Regular and thorough training programs ensure that all employees are aware of the latest safety protocols and how to use safety equipment effectively.

3. Open Communication: Encourage a culture where employees feel comfortable reporting hazards, near-misses, and safety concerns without fear of retribution.

4. Regular Safety Audits: Conduct frequent safety inspections and audits to identify potential risks and ensure compliance with safety standards.

5. Incentive Programs: Implement reward programs that recognize and encourage safe behavior among employees.

Regulatory Compliance and the Role of Government Agencies in Ensuring Safety

Regulatory compliance is a critical aspect of maintaining safety in the mining industry. Government agencies such as the Mine Safety and Health Administration (MSHA) in the United States play a pivotal role in setting and enforcing safety standards. Key elements of regulatory compliance include:

•Adhering to Safety Regulations: Ensure that all operations comply with local, national, and international safety regulations. This includes regular updates to safety protocols as regulations evolve.

•Documentation and Reporting: Maintain comprehensive records of safety training, incident reports, and safety audits. Accurate documentation is crucial for regulatory compliance and continuous improvement.

•Collaboration with Agencies: Work closely with regulatory bodies during inspections and audits. Open communication with these agencies can help identify areas for improvement and ensure adherence to best practices.

The Future of Safety in Mining: Predictive Analytics and Automation

The future of safety in the mining industry lies in predictive analytics and increased automation. These technologies promise to revolutionize safety practices by anticipating and mitigating risks before they become hazards.

•Predictive Analytics: By analyzing historical data and current conditions, predictive analytics can identify patterns and predict potential safety issues. This allows for proactive measures to be taken, reducing the likelihood of incidents.

•Automation and AI: The integration of artificial intelligence (AI) with automated mining equipment enhances precision and efficiency. AI can optimize machinery performance and anticipate maintenance needs, reducing the risk of equipment failure and accidents.

Conclusion

Safety in the mining industry is non-negotiable. The unique challenges posed by mining operations require a steadfast commitment to protecting workers through the adoption of advanced technologies, the establishment of a strong safety culture, and strict adherence to regulatory standards. As the industry evolves, so too will the methods for ensuring safety, driven by innovations in predictive analytics and automation. By prioritizing safety, mining operations not only safeguard their most valuable asset—their workforce—but also enhance overall productivity and sustainability.